AQUAFIN®-IC Art.-No. 2 04220 Crystalline waterproof slurry

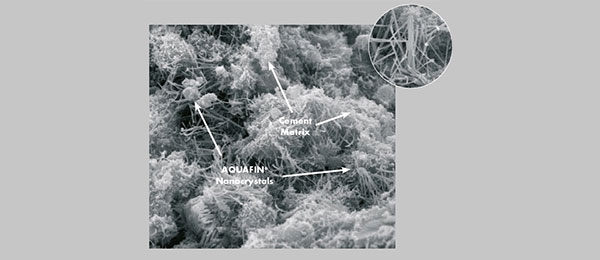

• Penetrates the capillaries in concrete.

• Continually active.

• Chloride free.

• Carbonatisation barrier.

• Can be applied to damp substrates.

• Resists high levels of hydrostatic pressure.

• Waterproofs retrospective cracks up to 0.4 mm.

• Test certificates to German DVGW worksheets W 347 and W 270 are available.

Areas of application:

• Exterior and interior waterproofing in cellars, lift shafts, foundations, floor slabs etc.

• Waterproofing containers for drinking and service water, retaining basins, water treatment plants, etc.

• Waterproofing beneath screeds (unbonded screeds or floating screeds). An analysis of the water is necessary where the hardness degree is ≤ ۳° dH. The determination of concrete aggression is carried out to DIN 4030. AQUAFIN-IC is resistant against strong chemical attack (exposure class XA2 to DIN 4030).

Technical Data:

Basis: sand/cement, additives Bulk density: 1.1 kg/l

Packaging: 25kg bags

Colour: grey

Mix: 25 kg AQUAFIN-IC to 6.75 to 8.0 litres clean water

Mixing time: 3 minutes (drill with 500 – ۷۰۰ rpm)

Pot life: 30 to 60 minutes (at +23° C / 60%) Substrate/Application

temperature: min. +5° C to max. +35° C. Lower temperatures extend, higher temperatures reduce curing times.

Impermeability to water in situ in accordance with PG MDS, (10 m water column): passed Cleaning of tools: With water when in the fresh state, remove dried material with ASO-R005.

Storage: dry, 12 months when stored in the original unopened packaging. Use opened packaging promptly. Material consumption: Ground moisture/ non standing

drainage water: 0.75 kg/m2 in one coat Non-hydrostatic

pressure: 1.2 kg/m2 in two coats Rising damp /

pressure water: 1.5 kg/m2 in two coats

Dry film thickness: min. 0.8 mm -1.5 mm Greater material consumption with uneven substrates is not taken into consideration.

Ready for exposure at +20° C and 60% relative humidity:

– to rain after approx. 24 hours

– to foot traffic after approx. 5 hours

– backfilling the building trench after 3 days

– filling containers after approx. 7 days Compressive strength: approx. 18 N/mm2 at 7 days

approx. 21 N/mm2 at 14 days

approx. 25 N/mm2 at 28 days

Water impermeability acording to CRD-C 48-92 (USA): 13 bar, negative or positive side

Substrate preparation:

The substrate must be sound, clean and have an open capillary structure. The surface must be porous and permit a good surface adhesion so that the active ingredients can penetrate well into the concrete. Horizontal areas should have a rough surface. Smooth surfaces must be mechanically abraded in order to achieve good penetration.

1. Remove all adhesion reducing substances such as dirt, cement laitance, release oils, loose components, paints and similar using sand-blasting, water jetting or other mechanical methods. Smooth substrates from shuttering must be acid-washed with ASO-R005 and then washed with plenty of water.

2. Eradicate all ridges, gravel pockets and other damaged areas. Defective construction joints and visible cracks (not dynamic) greater than 0.4 mm should be opened up to 20 mm in width and 25 mm in depth and repaired with ASOCRET-IM. Roughen anchoring holes.

3. Plug water leaks with FIX 10-S or Fix 20-T plugging cement.

4. Repair damaged areas with ASOCRET-BIS-system or ASOCRET-IM dependent on area of application.

5. Pretreat all connecting joints and construction joints with ASO-Joint-Tape-2000-S and AQUAFIN-RS300 or AQUAFIN-2K/M (please see respective Technical Data Sheets).

6. Pre-wetting all areas to be waterproofed with clean water is absolutely necessary. Repeated wetting produces saturation, which stops the absorption of the substrate whilst at the same time promoting the growth of crystals deep in the pores of the substrate. When applying AQUAFIN-IC, the surface should be mattdamp but not wet. Avoid ponding.

Product preparation:

Place 6.75 to 8 litres of clean water into a clean mixing bucket and mechanically stir (drill mixer at approx. 300 to 700 rpm) and mix in as much AQUAFIN IC until a lump-free, homogenous mass with either a slurry or sprayable consistency is achieved. Only mix as much material as can be used within 30-60 minutes. Allow to stand for at least 3 minutes then briefly re-mix.

Application:

Dependent on the project, application is to the positive or negative side of the exposure to water. Slurry application: In the appropriate quantity, apply two coats of AQUAFIN-IC at a slurry consistency with a roofers brush or wide hand-brush. Brush on evenly and thoroughly work into the substrate. Only apply the second coat when the first coat is still tacky and has not dried out. Prevent the first coat from drying out.

Spray application:

AQUAFIN-IC can be applied with suitable spray equipment such as e.g. HighPump M8 (Peristaltic pump), HighPump Small or HighPump Pictor (Screw feed pump). Information from HTG HIGH TECH Germany GmbH, Berlin, www.hightechspray.de. Dependent on the exposure conditions, spray apply one or two coats in a circular movement. Only apply the second coat when the first coat is still tacky and has not dried out. Prevent the first coat from drying out.

Setting and protecting:

a) Protect the fresh coating from weathering e.g. sunshine, rain and frost etc. Keep the waterproofing layer damp for at least 3 days whereby the first dampening is carried out one day after application and repeated at determined intervals. Where there is strong sunshine or wind exposure, we recommend the use of jute sheets soaked in water. The fresh coating should be protected from rain for at least 24 hours. Back-filling the building pit can take place 3 days after coating.

b) Internal areas:

In areas where there is high humidity, the material hardens very well. In relatively dry areas keep the coating damp for 3 days. In poorly ventilated rooms and deep building pits, ensure there is adequate ventilation for at least 24 hours.

c) Containers:

Filling is possible after 3 days. In potable water containers, these should be thoroughly rinsed with potable water before filling. AQUAFIN-IC is permanently active when correctly installed.

Important advice:

• Protect areas not to be treated with AQUAFIN-IC from its effects.

• AQUAFIN-IC cannot be used as an additive for concrete or renders.

• AQUAFIN-IC cannot be subsequently overcoated, e.g. with tiles, render, bonded screeds or coloured paints.

• With concrete containing fly-ash it is possible that successive coats of AQUAFIN-IC may discolour and there may be an impaired reaction. The flyash component according to ASTM C-618 type C may only be max. 30% of the binder. The minimum quantity of CaO in the fly-ash should not be below 15%. Please contact the Technical Service regarding particular specification for concretes with type C fly-ash with low CaO content, type F or other pozzolanic concrete additives.

• The reaction between AQUAFIN-IC and free lime in concrete can lead to minor efflorescence. This is not detrimental and can be removed with a brush.

• Different colourings are dependent on the differing dampness of the concrete.

• A load bearing surface is necessary for a long lasting bond between surface and coating system. Adhesion inhibiting materials have to be removed completely. High pressure (> 400 bar) or ultra high pressure (> 2000 bar) waterblasting and blasting with solid abrasives are suitable procedures. The final cleaning has to be carried out with water blasting.

• Temperatures around +10° C to +15° C are to be expected in water containers. In order to guarantee complete hydration of the cement, keep

the coating damp for an adequate length of time (constant relative humidity of > 80%) and protect against drying out. In general 7 days is sufficient. It is essential to avoid the formation of condensation or standing films of water during this time period. Where there is a danger of dropping below the dew point (condensation formation) install dehumidifiers until the mortar is cured. At no time should uncontrolled warm air be blown inside.

• To increase pot life/working time at higher temperature store material in a cool environment above +5° C and only expose to warm temperature shortly before mixing. Additionally use of cold water can also increase pot life/working time, if water addition is necessary.

• AQUAFIN-IC may need up to one month to achieve its maximum waterproofing properties. Influencing factors are ambient temperature, humidity, concrete composition etc.

Please observe a valid EU health and safety data sheet.

GISCODE: ZP1